What are Pool Balls Made of

This article is more than 2 years old

Been playing pool for some while and the toughness made you think what are pool balls made of. Well, you are at the right place, in this post we are not only going to tell you what material makes them but also little history so you can appreciate how much billiards/pool/snooker has contributed to the world indirectly.

Additionally, if you love this game you must also check out our updated list of Best Pool Cues and Pool Balls.

What are Pool Balls Made of

Billiard or snooker or pool balls today are made up of a plastic called Phenolic Resin or Bakelite. Currently, a Belgium company named Saluc Manufactures more than 80% of the world pool balls. Continuous research and improvement at molecular level enabled Saluc to take a major share of the world’s pool ball production. They claim a sophisticated 13 step process enabled them to produce a pool ball of high quality to remain playable for 20 years.

Before we get into history lets get little understanding of why out of so many plastics around Phenolic Resin or Phenolic Formaldehyde is used for pool ball manufacturing. This plastic is made by mixing Phenol with formaldehyde pretty obvious with the name itself. The properties of this compound are so favorable that it has become the number one choice to make the pool balls.

Who Invented Phenolic Resins

Leo Baekeland is credited with the invention of this very useful plastic. His precious invention founds application not just in pool or snooker or billiard balls but also in spacecraft, computers, machinery, coatings, radios and so much more. He made this breakthrough invention in 1907 in New York.

Phenolic resin durability and ability to take strong impacts with chipping has made material scientists around the world interested in how they can use it in different industries where durability is not compromisable.

How is Phenolic Resin Made

This plastic is made by mixing Phenol with Formaldehyde. Although it seems simple there are quite a lot of steps involved in making this plastic which of course goes out of scope for this post. The shared picture of a pool ball cut in half will give you an idea of how phenolic resins look. Usually, the balls are colored from outside and the resins are not colored themselves. So you can expect to see most of the balls with the same color from inside as shared in the below picture.

Why Phenolic Resins

Phenolic resins are almost perfect for the demands of the game of pool/snooker/billiards. There are quite a lot of properties of bakelite that prove that this is the ideal material to manufacture this great game balls.

VERY STRONG

Imagine playing a strong break shot with a strong tip and your cue ball shatters straight away. Well, that would be drastic and your club manager would probably kick you out. Or when you are trying to do a classic break with full power and the balls get shattered as the momentum gets transferred.

There can be so many possibilities, pool balls should never break at all. This is promised by Phenolic Resin’s molecular structure. It is very compact and has strong bonding which ensures no cracking of the ball.

TEMPERATURE INSENSITIVITY

You want your pool balls to don’t change shape whether playing on freezing cold artic or harsh Sahara desert. Phenolic resins can survive both extremes of the world so no matter wherever you play pool irrespective of the temperature balls are not going to be deformed.

EASE OF MANUFACTURING

Although Saluc has a very sophisticated manufacturing process Bakelite or Phenolic Resin certainly helps by its property that it can be easily molded into any shape.

UNIFORM DENSITY

Pool balls made up of phenolic resins have a uniform density from the surface to the core. This means that all your shots have equal likely probability of passing on the same momentum to the next balls irrespective to the point of contact made. If the balls did not have uniform density than the pool balls would have different momentum along the circumference.

INSENSITIVE TO ATMOSPHERE

Bakelite doesn’t react with the atmosphere and hence the balls would not decay or lose smoothness of the surface if left uncovered.

Scratch less

Game of Pool requires smooth movement of the ball along the cloth of the table. Imagine if the ball had too much friction then no matter how good you play the interaction of the friction of the cloth and balls would produce uncalculated results and that would not be fun. Bakelite pool balls remain smooth and ensure right angling.

Looks Good

Pool Balls have to look good. It’s a beautiful game especially with a clean set of pool balls on a new cloth makes the table looks great. Bakelite can be easily cleaned and kept shining to look great under the lights. Just need to wipe out the dust or the chalk due to impact with the tip.

Not Flammable

Although it may seem unnecessary but history has taught that the pool/billiard/snooker balls should not be flammable at all. To get a better gist of it you need to read little history below:

BRIEF HISTORY: HOW WE GOT HERE

Wooden Balls

In the beginning, wooden balls were used but they would crack easily because this game is based on the transfer of force.

Relentless Ivory Balls

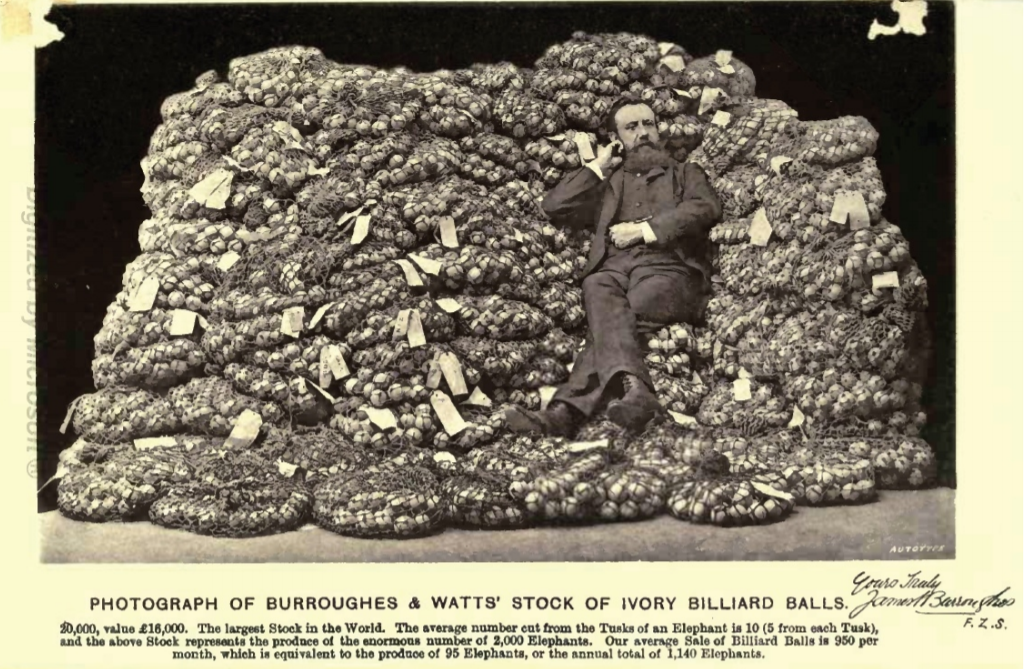

From wooden things shifted to expensive Ivory, first used by Duke of Norfolk. Ivory is obtained from Elephant tusks and that required to slaughter the giant mammal. Only 8 balls could be obtained from tusks of a grown-up elephant. But the problem was the ivory balls were not only very expensive but also they would break easily.

The third problem was the fading of the color. Ivory color would fade into yellow very soon and made the balls unattractive for the wealthy people. The fourth problem among the manufacturers was, the hunters could lose their lives in an attempt to kill the elephant for its tusks. Yes, that is correct people in that time were not much concerned about the endangerment of this beautiful animal. Look at the stock of ivory balls behind this man.

Parkesine

As ivory got more expensive and rare. Manufacturers realized that their business is going down a steep hill. So in the 19th century on the 10th avenue in New York, a manufacturer announced prize money of 200K USD in today’s worth for someone who could come up with an alternate solution.

So the race was on and a chemist made a new plastic from Cellulose, Sulphuric, and Nitric acid. This nitrocellular plastic was named to be as Parkesine. It was cheap and easy to mold the balls but like ivory, it also cracked easily.

Improved Parkesine: Celluloid

William Hyatt tried to improve this nitro cellular material ‘’Parkesine’’. There were gaps in molecular structure that needed plasticizer to fill the gaps and make the material non-cracking. Hyatt thought of using camphor found in laurel tree as an additive to add the strength. Hyatt named this material Celluloid and is considered the forerunner of modern plastic.

This plastic worked great it did not break like Parkesine but it was flammable and caused some accidents during production that made it riskier to manufacture.

Bakelite: The Breakthrough

Then in the 1900s, Leo Baekeland came up with his Bakelite as discussed above and till today with improvement in manufacturing process Bakelite is the material the pool balls are made of today.

Conclusion: What Are Pool Balls Made of

Pool balls are made of Bakelite or Phenolic Resins. It is one of the most important plastic ever made in human history. Not many people know but the beautiful game of billiard is behind the invention of this critical plastic.